Electronic manufacturing is heading towards a successful and improvised efficiency by revolutionizing PCB/Printed circuit boards. These automate the manufacturing process of electronic items and reduce the requirements of a point-to-point wiring system.

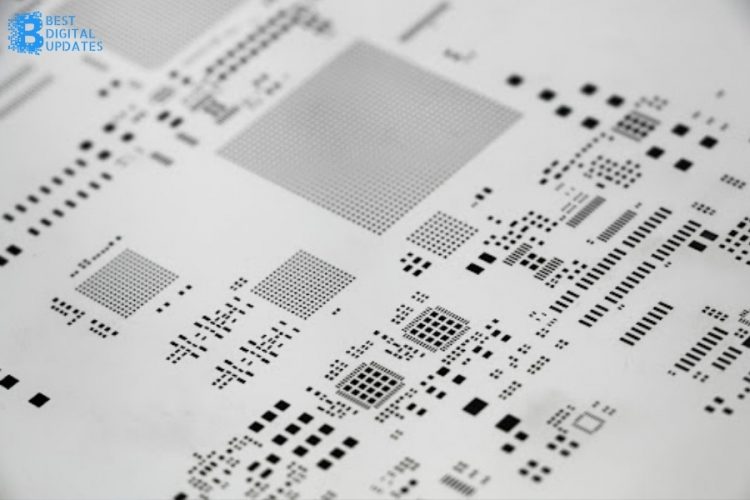

In this modern technology world, the manufacturers of PCB are using this technology for the component placement of advanced machines and SMT stencils for board assembly. Therefore, it is very essential to select a high-quality PCB stencil for your board assembly. They are of different types based on the manufacturing method, solder paste application in SMT, and used materials.

What is STM Stencil?

Table of Contents

STM stencils are used in the assembly board of electronic items. With the help of stencils, the manufacturers can apply deposit solder paste on wiring boards so that they can establish electronic connections. After establishing the connections, it allows the placement of components.

In this process, an adhesive solder paste and stencil is applied in stencil printing. This step helps in the placement of components to decide the positions. Now, there are many SMT stencils used in PCB assembly for the manufacturing of the electric device.

The technology of STM stencils

The solder paste is deposited on printing wiring boards (PWDs) to make electrical connections in the stencil printing process. Finally, the component placement stage completes. In this stage process stencils, solder paste, a printer and other equipment and materials are used.

It is popular in different regions, such as laser stencils, PCB stencils, or solder paste. In this process, the solder paste is transferred to a printed circuit board (PCB) due to its complicated designing circuit.

It is a pre-made template that transfers the solder paste to a naked PCB using an aperture layout. In which the stencils are made up of Steel, foil, ploy film, or other materials. Among these materials, steel foil is a widely used stencil material due to its high-quality printing.

What is the purpose of SMT stencils?

The main purpose of the STM stencil is to place the component onto a naked PCB after the application of a solder paste coat. These stencils allow a fantastic cutting of board, lower labour costs, and timely process execution. It also helps reduce manual placement of components that are useful to produce the same PCB.

One can get detailed information of calculation of stencil thickness from IPC 7525. The average value of stencil thickening should be 2.64 + 0.0831 * pitch-of-content.

SMT stencils have two various formats that are frameless and framed. Where frames are best suited for high volume print circuit boards, and the frameless foils are easily replaced for the mixed environment so that different PCBs are produced on the common line.

Different types of SMT Stencils

The manufacturing of SMT stencils takes place in various ways. They are of the following types:-

- Frameless Stencils – These stencils are fixed with the help of frames permanently.The border mesh of the circuit receives the necessary tension. These are vastly used in the production of PCB. They consist of smooth aperture walls that ensure an exclusive printing experience for the user.

- Frameless Stencils – These are not permanently fixed or mounted with a frame. They are more affordable and used for short purposes or prototype runs, comparatively.

What are the benefits of SMT Stencils?

A great SMT stencil is a must for PCB to resolve various issues in the electric board. It has the following exclusive benefits:-

- Lack of short Circuits – The application of solder paste may increase the risk of short-circuiting. But the use of SMT stencils is almost nil the chances of short circuits.

- Reduced gaps in the soldering process – The laser-cut stencils will help you apply an even layer of solder paste that fills the gaps in this process.

- Smooth pad walls –The SMT stencil will help apply a smooth pad wall desired by most PCB designers.

- Consistent Aperture –Inconsistency in the apertures may lead to unfixed stencils, and this will result in undesirable rough-looking PCB and will not work efficiently. But SMT will eliminate any issue or defects in the PCB and fix the aperture in the PCB.

- Exact pad position –The pad position is essential to get the perfection of the pitch during printing, which is only obtained by accurate positioning of the pad. An SMT cut will allow you to find the right pad position on the board.

- High-quality printing –With the help of SMT stencils, you can accurately print your PCB for your software. Using stencils, SMT will allow you to get the highest quality smallest pattern, such as a 250 micro micron.

Solder paste printing and painting your house are almost similar, but the only difference between them is that solder paste should be applied to a particular space and volume. In addition, it should be controlled and precisely deposited. For perfection, use a special steel plate with a stencil to control the process of printing solder paste. Also Raed about the benefits of 3D Scanner.