A staggering 30,000 new products hit the shelves every year, which shows the importance of using labels to cut through the noise.

Labels are an effective way of supporting your brand’s identity and displaying essential information through attractive design. But choosing the right method of label printing is important as each one produces different results. Maybe that’s why you’re here; you want to learn about the various options and deepen your knowledge.

Sounds like you? No worries, we’ve got your back. Here are the different types of label printers available.

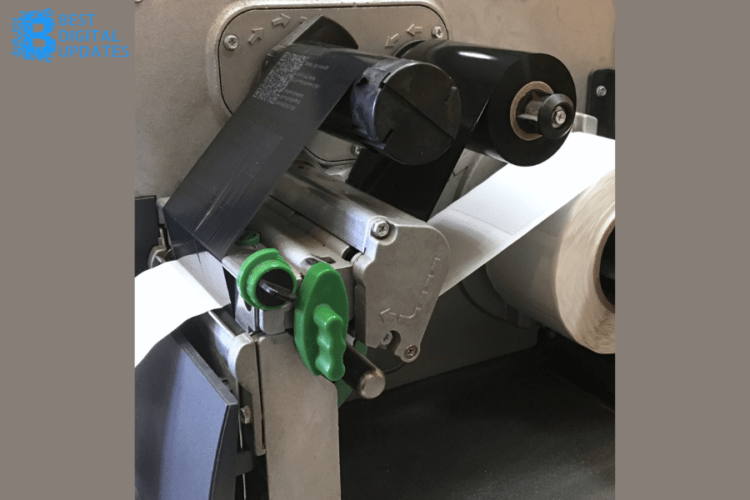

Thermal Transfer Label Printers

Table of Contents

When printing labels, many business owners go with thermal transfer printers. These produce durable labels and can print a huge number at once, which is great if you must prepare a large order. Note, that the cost of this commercial printer includes paper and plastic film.

Direct Thermal Label Printers

If you’re familiar with the different types of label printers, you’ll have heard of this one. Direct thermal printers have a sheet of chemicals underneath the surface that create images once exposed to heat. Although it’s the more affordable option, you’ll notice that the labels aren’t durable and aren’t as vibrant as other color label printers.

Inkjet-Based Label Printers

Another popular type of commercial printer is the inkjet-based model. This is the go-to business printer if you’re after vibrant, professional labels. The beauty of this option is the labels are water-resistant and can withstand exposure to UV lighting.

Toner-Based Label Printers

Business owners can also benefit from a toner-based label printer. Unlike inkjet-based printers, toned-based machines use dry toner to produce labels, so they can print both white and CYMK colors. A bonus is that toner-based label printers are compatible with a variety of materials, which gives businesses more flexibility.

Flexographic Label Printer

If you’re set on buying a label printer, consider a flexographic label printer for your business. Otherwise known as “flexo printing”, this produces thousands of labels instantaneously and laminates them in a single process. But this is a far higher startup cost for flex printing because you need a unique mold before you can start printing.

Screen Printing

Screen printing is where you transfer a design onto labels by hand, so it’s not practical for mass-producing labels. But once you’ve created the stencil design and chosen a color, you get a unique look that will stand out from other products on the shelves.

But it’s important to note, that when you have multiple colors, it makes it harder to produce the labels. This is because you need a screen for each color, so it’s easier to go with one or two maximum.

Check Out the Different Label Printers Today

Hopefully, you’re now an expert on the different label printers available.

There are many options for label printing, such as choosing a thermal transfer printer or a direct thermal one. Businesses can also try screen printing or a flexographic printer, depending on their needs. Good luck!

Informative read? Great to hear! Then, check out the rest of our blog for more great content.

![[pii_email_e6685ca0de00abf1e4d5]](https://bestdigitalupdates.com/wp-content/uploads/2021/06/pii_email_e6685ca0de00abf1e4d5-75x75.jpg)

![[pii_pn_8a68e8c174733080624b] error](https://bestdigitalupdates.com/wp-content/uploads/2020/12/pii_pn_8a68e8c174733080624b-error-75x75.png)